HPY prides itself on being “the manufacturer of the world's most diverse and efficient ore sorting product line,” and this is successfully proven by the newest technical upgrades done on Shenzhen Zhongjin Lingnan Nonfemet’s Fankou Mineral Processing Plant and the Construction Material Plant this year.

Through the strategic use of all new models of HPY’s sensor-based sorting machines, Fankou’s Mineral Processing Plant has experienced a transformation in the sorting system. The mine could now sort coarse particle-sized ores using HPY’s Golden Coal Series, elevating efficiency in the semi-autogenous mill, reducing the energy consumption of the whole system, and significantly reducing the mine’s tailings pond. Previously, Fankou had already had an impressive $2.9 million annual revenue increase since introducing four HPY Classic Series sorters. Currently, one Circle Series XRT sorter has the same sorting capacity as two conveyor-belt sorting machines; the most recent technical upgrade allowed Fankou to replace four Classic Series sorters with two Circle Series sorters, reducing electricity usage by 14 times. These figures demonstrate the significant financial benefits that can be achieved using HPY technology.

Resource Utilization Struggles for One of Asia’s Largest Lead-Zinc Mine

In the article, “Maximising the benefits of sensor-based ore sorting machines,” published in April 2023, HPY Technology outlined how the cooperation project came together.

Fankou’s two process plants, the Mineral Processing Plant and the Construction Material Plant are situated in Renhua County, Guangdong, China, and have a long history. Once one of Asia’s largest lead-zinc mines, this mine faced significant challenges as the years passed. As Mr. Luo, the plant's general manager, explains, “In its peak year, it could deliver approximately 180,000 tons of lead-zinc. However, after over 60 years of production, depleting resources and accumulating waste rock piles forced the mine to take drastic measures to modify the entire processing chain.” Hence, it underscores the necessity for innovative solutions like HPY's machines in the mining industry.

Fankou’s entire modification plan was ambitious; its total budget was estimated at 27.6 million US dollars since it needed to properly lay the groundwork and renovate the building, adding HPY’s ore sorting step to the process flow fitted nicely within its grand plan of upgrading its overall mining process.

1st Upgrade: Special Research Project for Profitable and Responsible Mining

At the end of 2017, Fankou’s executive team went to HPY Technology’s testing center to carry out preliminary sorting tests. Mr. Luo noted, “There were few companies in China that did sensor-based sorting at the time; in addition, Fankou’s lead-zinc was considered by many the ‘hard-to-sort’ type.” Although the results weren’t mature yet, the team is still pleasantly surprised at the promising results. Not long after, HPY and Fankou’s team decided to approach this project as a research project in 2018; the two parties agreed HPY would form a dedicated team to conduct specialized research on providing the most economical and technically responsible lead-zinc sorting solutions for the Fankou Project. It did not take long for satisfactory results for both sides to start coming in. HPY successfully fulfilled its mission in 2019, and the machines were officially added to the plant thereafter.

Fankou’s mineral processing plant initially used four Classic Series P60-X1400 ore sorting machines. The machine processes the particle size range of +10-90 mm, which accounts for about 50% of the raw ore. This accounts for 2,600 tons of ore, rejecting 400-500 t/d of waste rock. After pre-concentration, the lead and zinc content in the waste rock is below 0.3%, and the sulfur and iron content is below 3.8%. Therefore, the ore sorting process enriches the ore grade by 1.08% for lead and zinc and 2% for sulfur and iron.

This sorter is the typical conveyor belt metal separator in China, and similar designs are also seen everywhere else. Its stable performance and cost-effectiveness are more often the reasons for its purchase.

The project highlighted how HPY’s boosted machinery throughput had positively impacted the safety aspect of the mine’s mining practice; the mine can now mine more areas by vertical blasting, eliminating the risk of personnel working underground entirely.

Mr. Luo commends HPY’s updated ore sorting machine for completely changing the way Fankou mines: “Due to the depletion of mineral resources and the Chinese government's increasing emphasis on the ESG aspect of the big mines, we did underground mining before discovering the option of HPY sensor-based sorting. However, not only is the production rate not ideal, but because the space in the underground channels is very narrow, we need personnel to attend to the errands, which makes the mining production very low and extremely unsafe.” He then adds, “After vertical crater retreat and large blasting, a large number of tailings, and the unnecessarily high cost generated in the mills during the processing can be significantly reduced with an ore sorter; all we need to do is send in carts, have it shoveled onto the bin, and have it crushed, screened and cabled to the sorters.”

Since its installation, HPY Technology has upgraded its entire product line. With an enhanced sensor detection system and a remodeled module design that allows for easy maintenance, HPY’s machines' processing capacity significantly improves compared to the older models. By March 2023, after using HPY’s machines for four years, Fankou – now a ‘royal customer,’ was open and excited for another round of machine upgrading to increase the amount of sorted material.

2nd Upgrade: Boosted Processing Capacity and Safe Lead-zinc Extraction

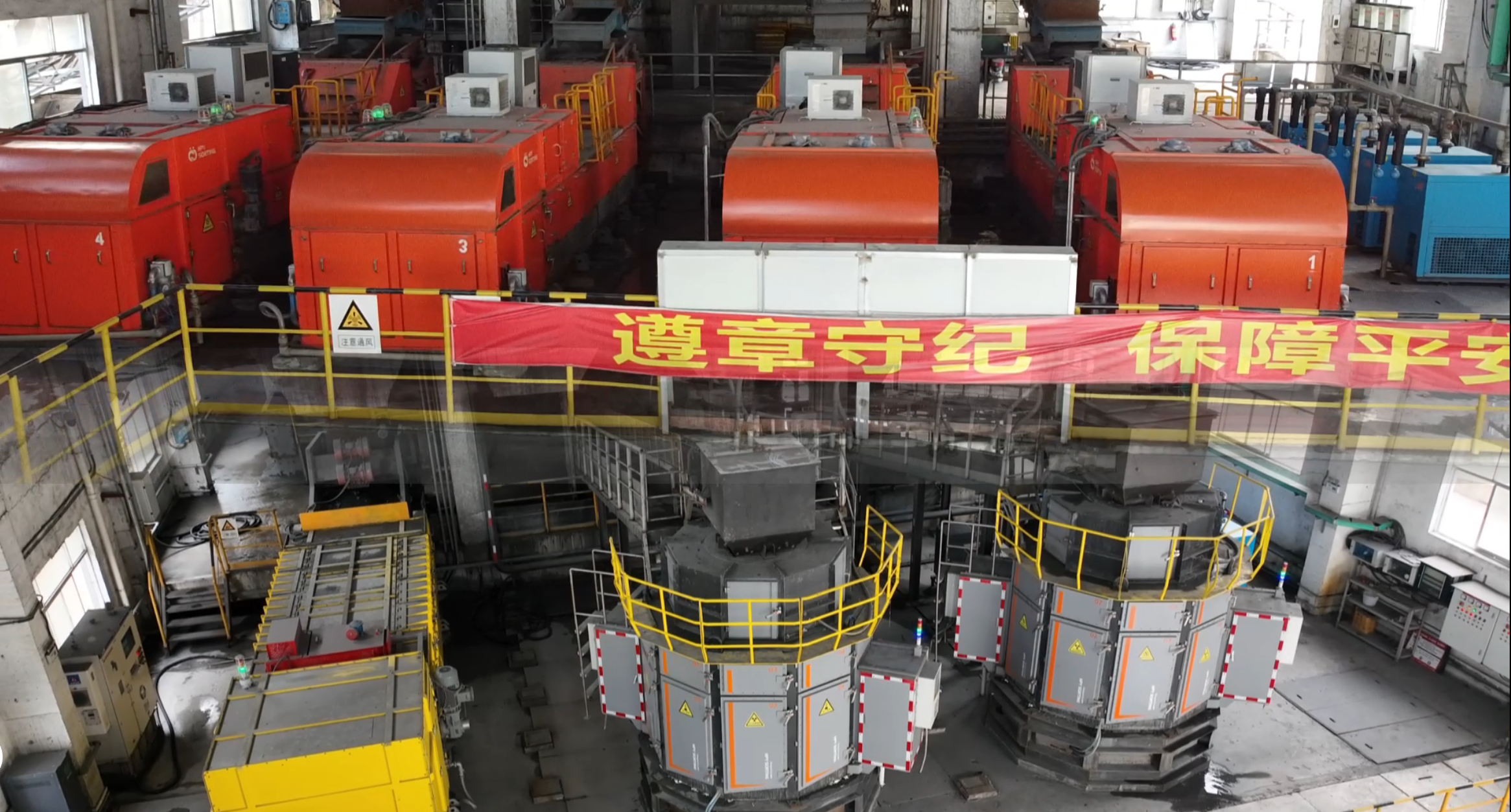

Upon HPY's advice, the Fankou Mineral Processing Plant switched its four Classic Series to two Circle Series and one Golden Coal Series (See Figure 2). The Golden Coal Series was previously made to sort coal; after some updates and redesign by the HPY R&D team, it is now made specially for large particle-sized ore sorting. In Fankou’s case, +40mm-90mm sized ores will enter the Golden Coal Series for pre-concentration. As for the two Circle Series on the side, their expertise lies in their accuracy in sorting and large processing capacity that could replace two typical conveyor-belt sorters with one machine. Their particle size ranges from +10-40mm, considering those are the major distribution sizes produced during the initial screening process in Fankou. However, according to Mr. Luo, Fankou is still in the process of optimization now that the upgraded machines could process greater size distributions: “In the past, ores that are larger than 90mm will enter straight into the semi-autogenous mill process, we plan to increase the Circle Series particle size to +10-60mm and feed the +60-150mm to the Golden Coal Series, this will help us increase the efficiency of the semi-autogenous mill process even more” said Mr. Luo.

The ore sorting process modification consists of first removing one Classic Series and replacing it with a Golden Coal Series. The installation and training process took one month, and by June 2023, the Golden Coal Series was running at total capacity. The two Circle Series’ implementation stretched longer as the mine could only halt its production for installation during more extended holidays in October 2023 and February 2024. Therefore, it took the entire Fankou Mineral Processing Plant a year to update all of the ore sorting machines (See Figure 3).

As mentioned before, the processing capacity prior to the update was around 2500~2600t/d; after the machine update was completed, it went up to 3500t/d. A benefit of this update is that the Circle Series has less power consumption; thus, more revenue is generated from the sorted ore. The circular vibrating material layout maximizes the symmetrical mass of the disc, requiring minimal excitation force to drive the ore toward the circumferential direction evenly. This significantly reduces energy consumption compared to traditional feeders, which rely on excitation force to move under their own weight. Compared to belt-type ore sorting equipment with a width of 1.4 meters, the energy consumption of this 1.5-meter diameter disc feeder machine can be reduced from 7.5 kW to 0.75 kW.

| HPY Technology | Fankou lead-zinc Mine, Mineral Processing Plan | |

|---|---|

| Machine used | One Golden Coal Series | Two Circle Series |

| Processing capacity | 3,500 t/d |

| Particle size | +10-150 mm |

| Concentrated ore grade | (Pb+Zn) 12% (most economic ore grade) |

| Waste rock grade | (Pb+Zn) <0.3% |

| Grinding grade | (Pb+Zn) increased by 1.08% |

| Rejection rate | 16-17% |

The Chinese government ordered Fankou to close its tailings pond by 2025. Thanks to the support of HPY Technology Golden Coal Series coarse particle sorters, Fankou is able to effectively decrease its tailings pond and have 58% leftover tailings for backfills. In the close circuit of the Fankou Mineral Processing Plant, every resource is utilized, and not a single ore has gone to waste.

“At HPY, we are focused on exploring paths that may revolutionize the mining of natural resources and pushing forward sustainable extraction through our expertise in resource management,” says Coral Lin, Manager of HPY Branding Department. The case has been thoroughly proven for the last seven years of working with Fankou Lead-Zinc Mine; whether it’s in devising a customized research solution or providing machine upgrade support to optimize the process years later, HPY’s holds a pivotal position in shaping the future of mining in a profitable and minimal ecological footprint direction.

About HPY

HPY Technology Co., Ltd is a high-tech enterprise that specializes in developing and manufacturing ore sorting machines that use cutting-edge AI technology such as perception technology, human-computer interaction, and deep learning. As a trailblazer in the Chinese mining industry, HPY Technology accomplished the first cases of ore sorting in China for over 30 ore types. This innovation not only revolutionized traditional mineral processing but also made a significant contribution to the technological advancement of the global mining industry. The company headquarters in Ganzhou, Jiangxi Province, covers an area of 68,000m2, including Asia’s largest mineral processing laboratory and a well-equipped engineering research center. HPY Technology has an R&D center in Shenzhen, China's Silicon Valley, and branches in Beijing, Inner Mongolia, Yunnan, and Anhui, with over 400 employees. Since its establishment in 2015, the Ministry of Land and Resources of China and the China Nonferrous Metals Industry Association have officially recognized HPY Technology as an important contributor to the Chinese mining industry. In 2022, HPY Technology reached a benchmark of selling 400 ore sorting machines.